HOW BIOGAS SYSTEMS ARE DESIGNED

TO RUN ON YOUR DAIRY SLURRY.

HOW BIOGAS WORKS

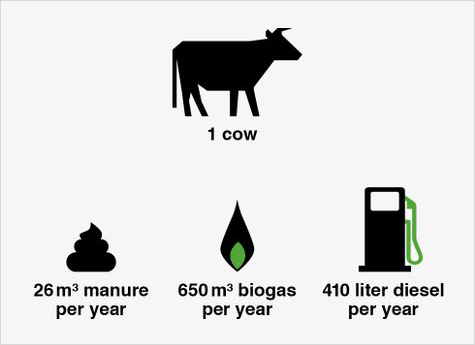

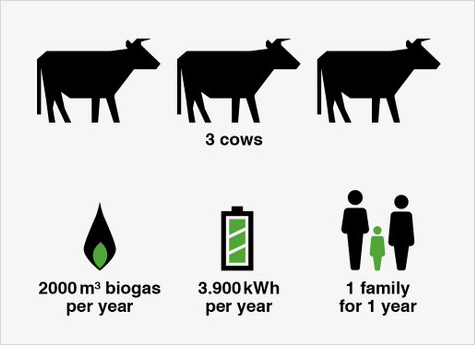

On a farm with 80 cows the yearly CH₄ emission of manure is equal to the CO₂ equivalent of 110 ton per year (that’s about 110 cars on the road).

By placing a Biolectric biogas installation on your farm this waste and its CH₄ emission are converted into green energy and heat, which can be used on the farm. The residual manure can be used as fertiliser

The Biolectric biogas installation daily pumps a fixed quantity of manure from the reactor to the digestate storage and repletes the discharged volume with fresh manure from the manure pit. This process is fully automated and is done under supervision.

Biogas is formed in the reactor through anaerobic fermentation. The gas is then purified and in the combustion engine it converts to green energy. This energy can be used on the farm in the form of electricity and heat.

BIOLECTRIC MICRO SCALE AD PLANT

HOW DOES IT WORK?

The Biolectric biogas installation daily pumps a fixed quantity of slurry from the reactor to the digestate storage and replaces the discharged volume with fresh manure from the manure pit. This process is fully automated and is done under supervision.

Biogas is formed in the reactor through anaerobic fermentation. The gas is then purified and in the combustion engine it converts to to green energy. This energy can be used in the form of electricity and heat on the farm.

Biolectric systems are classed as micro AD because of the size of energy output i.e. 11-75kw and the benefit of installing these smaller sizes is that we can match the power usage of the farm to gain maximum efficiency and therefore greater returns. Larger AD plants export a great percentage of their electricity which is only worth around 50% value and cannot use all the available heat. Matching the size to the farms usage is not only the most efficient but is the most environmentally conscious option.

DID YOU KNOW THAT…

Anaerobic digestion (AD) is the breakdown of organic material by micro-organisms in the absence of oxygen. AD produces biogas, a methane-rich gas that can be used as a fuel, and digestate, a source of nutrients that can be used as a fertiliser. Increasingly AD is being used to make the most of our waste by turning it into renewable energy.

Biogas is a mixture of around 60% methane, 40% carbon dioxide and traces of other contaminant gases, Biogas can be combusted to provide heat, electricity or both.

Combined Heat and Power (CHP)

Combined heat and power (CHP) is the simultaneous production of useable heat and electricity. As the process of AD requires some heat it is suited to CHP and this is currently the most popular option for UK plants. Whilst coal and gas-fired power stations have an efficiency of around 34% and 55% respectively, CHP plants can achieve overall efficiencies in excess of 80% at the point of use.

The ratio of heat to power varies dependent on the scale and technology, but typically 35-40% is converted to electricity, 40-45% to heat and the balance lost as inefficiencies at various stages of the process.

The Energy Produced

On a farm with 80 cows the yearly CH₄ emission of manure is equal to the CO₂ equivalent of 110 160 kg per year. By placing a Biolectric biogas installation this CH₄ (Methane) is converted into green energy and heat, enough to replace 110 cars off the road every year.

100+

EUROPE

INSTALLATIONS

110,160kg

ANNUALLY

CH4 EMISSIONS SAVED

110

EQUIVALENT TO CARS OFF

THE ROAD EACH YEAR

© 2024 Biolectric. All rights reserved

© 2024 Biolectric. All rights reserved