FAMILY OWNED FARM

GLOUCESTERSHIRE

The Farms Story

Court Farm is a family run business located on the Gloucestershire/Herefordshire border, milking 260 Holsteins via 4 x Lely astronaut robots. The 260 acre farm is an excellent example of how the 75 year old business is embracing new technology to improve efficiency and increase sustainability.

Richard Carter is the son in law of Mr & Mrs C Pugh who own the farm and we asked why they looked at farm scale AD?

“We saw it as a good add on to our business to use a waste product which is our slurry to produce electricity and heat. it was a similar investment to having another robot and more cows, however we don’t have to manage it in the same way. e.g we don’t have more acres to farm, no extra livestock and no extra slurry to manage”

And asked if the Biolectric system has benefitted the farm?

“It has reduced our £35000 electric bill by 80% so far, and we are also going to receive feed in tariff and RHI, and there are some hidden benefits as the digestate has a higher fertiliser value which in turn will reduce our bought in fertiliser costs, we do feel it will put us in a better place for any future environmental legislation. ”

The biolectric system sounded like the solution they had been looking for which would generate renewable electricity and hot water 24/7 and leave them with digestate which can improve grass growth when spread effectively.

Energy Use

With electricity rising at an alarming rate the electricity and heat savings will save us in excess of £50 000 per annum

The hot water produced will provide heating in the Farmhouse & cafe along with hot water for the robots and washdown will provide additional savings.

Key Facts:

Slurry Only Biolectric Micro AD System

Size : 33kw (11 & 22kw CHP Engines)

Key Benefits:

Excellent financial returns

Reduced fertilizer costs

Protection from future environmental legislation

What does the farmer have to say?

What would you say to any farmer considering a Biolectric system?

“It is a great add on to any dairy farm. However a good knowledge of how the plant works in terms of being able to carry out any repair/maintenance is vital to achieving good results and profitability. We spend between 5-15 minutes a day just making sure everything is ok, You cant just forget about it.”

Mr Richard Carter – Court Farm

DID YOU KNOW THAT…

The inspiration of Biolectric originated in 2009 after seeing that there were no mass produced micro scale AD plants in Europe. After building a proof-of-concept installation in 2011, Philippe Jans – reinforced by the investor he found in the family Westerlund (Taste Invest) and together with Jan Palmaers and Jonathan Schrauwen – established Biolectric.

Since building the first micro digester the system has seen many technical innovations (some patented) that has increased reliability.

The Energy Produced

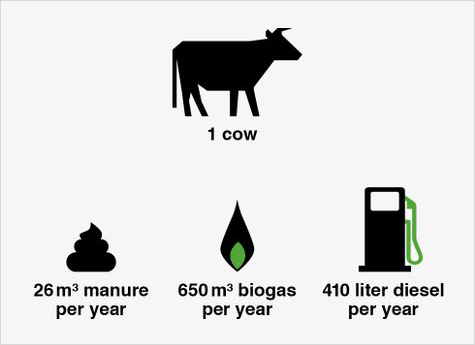

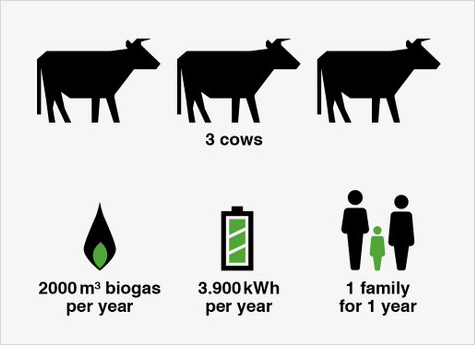

On a farm with 80 cows the yearly CH₄ emission of manure is equal to the CO₂ equivalent of 110 160 kg per year. By placing a Biolectric biogas installation this CH₄ (Methane) is converted into green energy and heat, enough to replace 110 cars off the road every year.

100+

EUROPE

INSTALLATIONS

110,160kg

ANNUALLY

CH4 EMISSIONS SAVED

110

EQUIVALENT TO CARS OFF

THE ROAD EACH YEAR

© 2024 Biolectric. All rights reserved

© 2024 Biolectric. All rights reserved